Sportswear & Footwear

Accelerating athletic innovation through digital twins of physical tests

From Concept to Design, with Unprecedented Accuracy and Speed

Athletic footwear typically takes 18 months from concept to market. In today's competitive landscape, that's too slow. Brands must innovate faster, use less material, enhance performance, and hit aggressive price points—all while adapting to new material innovations.

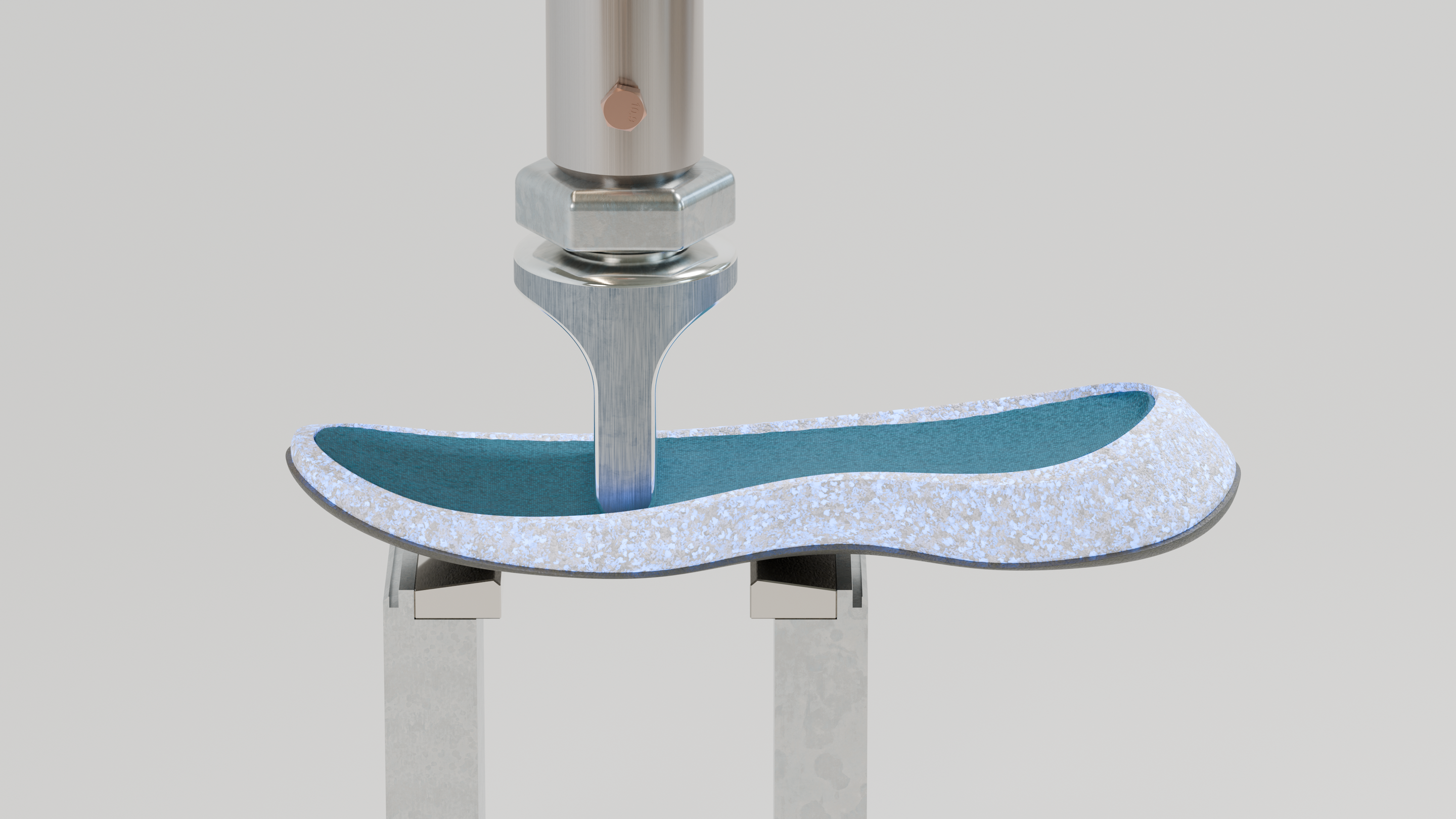

Metafold's Geometric Intelligence™ platform cuts months off development cycles. Our validated digital twins of physical tests—compression, shear, 3-point bending—enable teams to evaluate thousands of designs in hours instead of waiting 3-6 weeks per physical prototype. When your materials team develops a new proprietary foam, instantly calibrate it and test across your entire product line. Systematically find the optimal balance of weight reduction, performance, and sustainability without the traditional trial-and-error approach.

Leading brands using our platform achieve 95% faster iteration cycles and 20%+ material reduction.

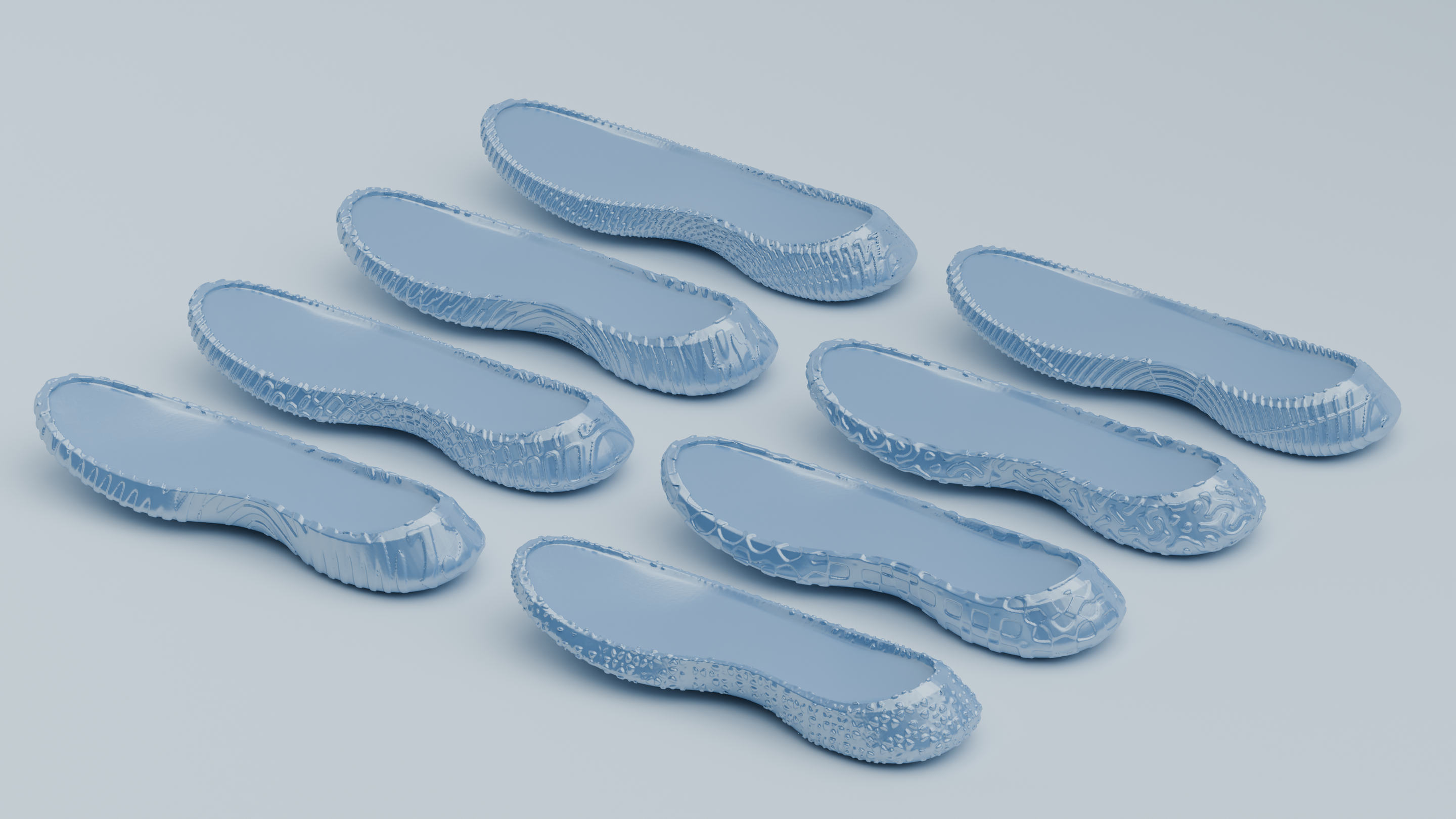

Full Design Space Mapping

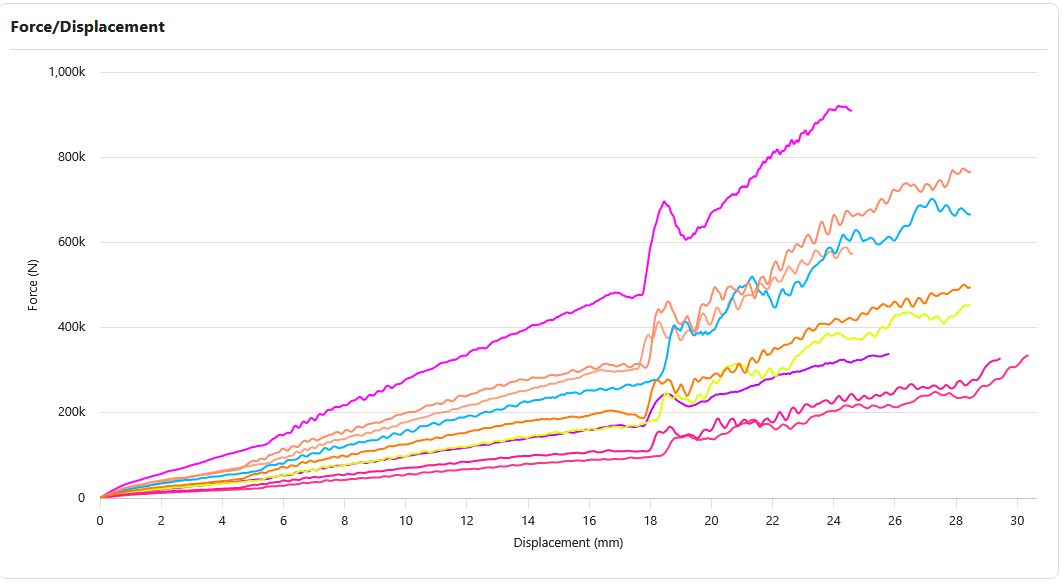

Advanced digital twins of physical tests enable rapid exploration of design spaces for Advanced Footwear Technology and high performance sportswear. Launch thousands of performance predictions in parallel to test combinations of foam densities, outsole patterns, and plate geometries. Replicating your standard physical tests in a digital workflow (compression, shear, 3-point bending etc), Geometric Intelligence™ optimizes across many design and performance requirements.

High Fidelity Material Calibration

Your proprietary foam and rubber materials are precisely calibrated to match physical test data, ensuring digital simulations accurately predict real-world performance. Validate energy return, durability, and comfort metrics before committing to expensive prototyping cycles.

Case Study: Fortune 500 Sportswear Leader

A major athletic brand transformed their R&D process using Metafold's platform to meet aggressive performance targets. The results included:

- 95% reduction in development time through digital testing replacing 6-week physical prototype cycles

- 20% weight reduction in midsole component geometry with maintained performance metrics

- 1000+ designs evaluated in half a day vs. 5-10 over several months

- 10,000+ training examples generated weekly for future AI model development

- Breakthrough performance achieved through systematic Design of Experiments approach

These improvements led to faster time-to-market, reduced material usage aligned with the brand's sustainability goals, and creation of a proprietary dataset positioning them for AI-driven design in the future.

Why Leading Sportswear Brands Choose Metafold

From 6 Weeks to Half a Day

Replace 6-week physical prototype cycles with half-day digital validation. Our calibrated digital twins replicate your standard tests, enabling you to test 1000+ midsole variations instead of just 5-10. Cut months off your 18-month development timeline.

Proprietary Material Advantage

Your foam innovations are your competitive edge. Our simulations match physical test results with validated accuracy, letting you optimize for weight, energy return, and durability simultaneously—achieving 20%+ material reduction without compromising performance.

Sustainable Performance at Scale

Meet aggressive sustainability targets while enhancing athletic performance. Test thousands of design-material combinations to find optimal configurations that use less material, perform better, and cost less. Every simulation generates training data for future AI models—turning today's R&D into tomorrow's competitive advantage.

Ready to Accelerate Your Athletic Innovation?

Join leading sportswear brands achieving 95% faster iteration cycles and 20%+ material reduction. Transform your R&D process with digital twins of physical tests.