Aerospace

Driving radical lightweighting and eliminating redundant engineering through breakthrough geometric analysis

From Decades of Data to Decisive Innovation

Aerospace manufacturers face extreme demands: significantly reduce weight while maintaining safety margins, navigate complex certification requirements, and manage decades of engineering history across incompatible CAD formats. Every gram matters when fuel costs millions, yet teams waste years recreating parts that already exist somewhere in their vast catalogs.

Metafold's Geometric Intelligence™ platform addresses both challenges. Our validated simulations enable systematic lightweighting through thousands of design iterations—testing different manufacturing approaches within DFM constraints. Meanwhile, our geometric search instantly identifies similar parts across your entire history, regardless of CAD format or age, potentially saving years of certification time and millions in redundant engineering.

Safran and other industry leaders use our platform to achieve 50%+ weight reduction targets while standardizing decades of geometric knowledge into actionable intelligence.

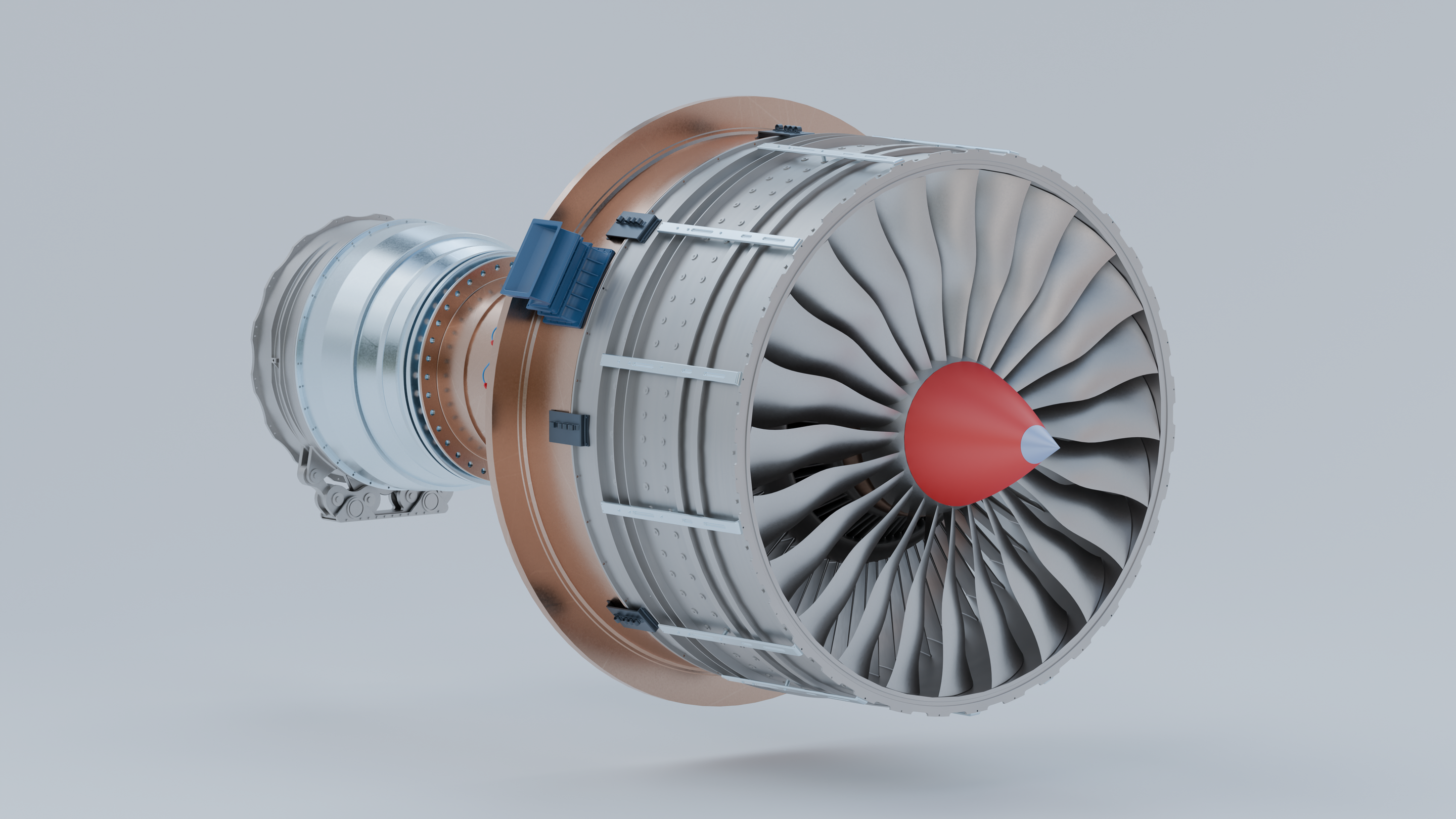

Radical Lightweighting Through Design of Experiment

Systematic Design of Experiments at unprecedented scale for aerospace applications. Test thousands of configurations against aerospace-specific loading conditions. Our high performance simulations replicate standard physical tests while exploring both conventional and additive manufacturing methods within precise DFM constraints, targeting aggressive weight reduction without compromising structural integrity.

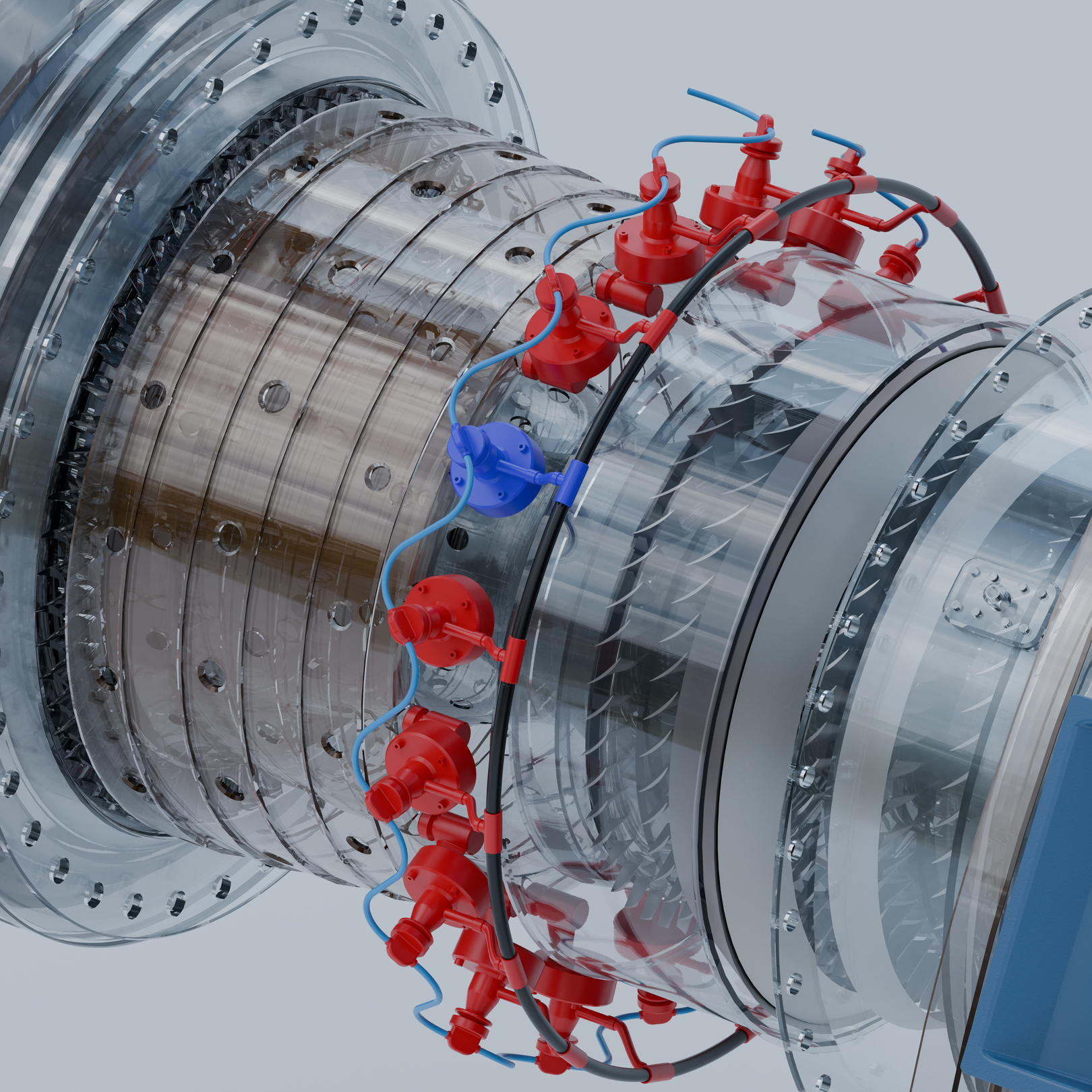

Geometric Search & Standardization

Transform decades of CAD data across all proprietary formats into a searchable geometric inventory. Instantly identify if similar parts or configurations exist anywhere in your catalog, eliminating redundant design work and leveraging existing certifications. Our platform standardizes your complete 3D data history — saving years off certification timelines and millions in engineering costs.

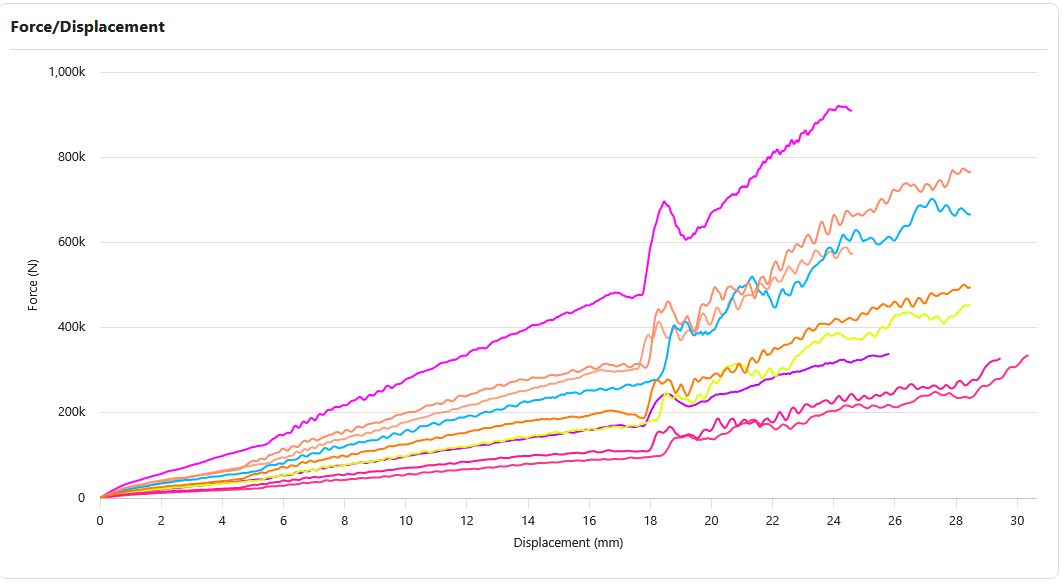

Case Study: Aerospace Lightweighting Initiative

A global aerospace leader partnered with Metafold to optimize critical components for their next-generation aircraft. The results included:

- 50%+ component weight reduction target identified through systematic geometric optimization

- Thousands of design variants evaluated for additive manufacturing

- Maintained form, fit and function ensuring no field changes required for part installation

- Months saved in development through parallel simulation replacing sequential physical testing

- Unified geometric database created from decades of legacy CAD formats

These improvements position the company to achieve radical weight savings critical for fuel efficiency and emissions targets, while building a searchable knowledge base of all historical designs for future programs.

Why Aerospace Leaders Trust Metafold

50%+ Weight Reduction Potential

Systematic lightweighting through Design of Experiments at unprecedented scale. Test thousands of configurations for conventional or additive manufacturing—all validated through digital twins of standard tests. Our implicit kernel handles the complex geometries that break traditional CAD systems.

Years Off Certification Timelines

Find similar parts instantly across your entire history, regardless of CAD format or age. When you identify existing certified designs or configurations, you eliminate redundant testing and accelerate approval processes. Transform decades of engineering knowledge into searchable intelligence that saves millions in development costs.

Fleet-Wide Optimization

Process millions of components across your entire catalog to identify lightweighting opportunities. Our cloud-native platform scales from single part analysis to enterprise-wide initiatives. Standardize geometric data from any legacy format—turning 30 years of mixed CAD systems into unified, actionable intelligence for next-generation aircraft.

Ready to Transform Your Aerospace Manufacturing?

Join aerospace leaders achieving 50%+ weight reduction targets through Geometric Intelligence™. Get started with our team to explore lightweighting opportunities and geometric search capabilities for your components.